Ejima ịghasa plastic extruder (PET mpempe akwụkwọ extrusion)

Nka nka

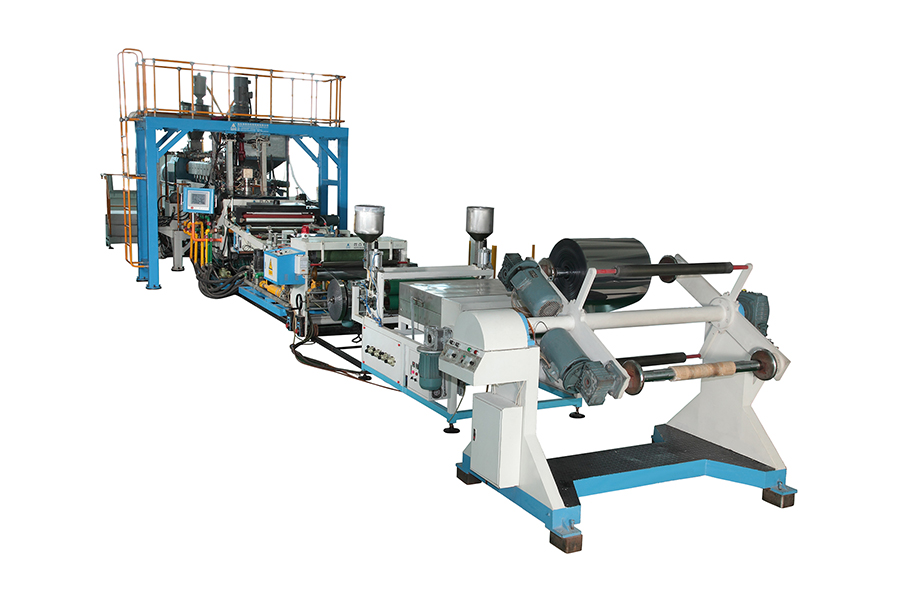

WJP(PET)75B-1000 Ejima ịghasa Plastic Extruder (PET mpempe akwụkwọ extrusion)

| Ngwa ngwa | Nkọwa nke ịghasa | Ọkpụrụkpụ mpempe akwụkwọ | Obosara mpempe akwụkwọ | Ike extrusion | Ike arụnyere |

| mm | mm | mm | n'arọ/h | kW | |

| APET, PLA | Φ75 | 0.18-1.5 | ≤850 | 300-400 | 280 |

Atụmatụ

1.The ịghasa mmewere adopts conjugate ụdị abụọ eri ịghasa na kọmputa njikarịcha imewe na nkenke machining. E wezụga nke ahụ, a na-eji ihe owuwu modular multivariate jikọtara ọnụ mee ihe nkedo ahụ, nke nwere nhicha onwe ya na mgbanwe mgbanwe.

2. Dabere na afọ nke ịhịa aka n'ahụ nhazi nhazi, AUTO nwere ike ịrụ nhazi kachasị mma nke ihe nchikota site na enyemaka nke teknụzụ ngwanrọ. Ya mere, ọ nwere ike na-aghọta nnyefe nke plasticizing ihe, agwakọta refining, ịkpacha ajị na dispersion, homogenization, volatilization na devolatilization, na-nrụgide na extrusion na ndị ọzọ ọrụ dị ka ndị ahịa ihe na nhazi teknụzụ.

3. A na-emepụta gbọmgbọm igwe ahụ na njikọ abụọ na-agwụ ike na-agwụ ike na-eme ka ikuku mmiri na gas ndị ọzọ na-agbanwe agbanwe.

4. The ejima ịghasa plastic extruder e mere na gbazee dosing mgbapụta n'ịhụ quantitative mmepụta na otu ebe mgbali, nke nwekwara ike inyere ghọta akpaka mechiri emechi-aka akara nke nrụgide na ọsọ.

5. Mkpokọta igwe na-anabata usoro njikwa PLC, nke nwere ike ịghọta njikwa akpaaka maka ntọala paramita, ọrụ ụbọchị, nzaghachi, egwu na ọrụ ndị ọzọ.

Uru

Otu n'ime isi ihe dị mkpa nke ejima ịghasa plastic extruders bụ ihe ịghasa ha. A kpachapụrụ anya nke ukwuu iji hụ na arụmọrụ na ịdịte aka kacha mma site n'iji screw ejima ejikọtara ọnụ. A na-ejikọta atụmatụ a pụrụ iche na teknụzụ njikarịcha kọmputa na nhazi nke ọma, na-ebute arụmọrụ dị elu. Ihe ndị ahụ skru na-egosipụtakwa ihe owuwu modular maka nhicha onwe ya dị elu yana mgbanwe. Nke a na-eme ka usoro mmepụta ihe dị mma na nke na-adịghị akwụsị akwụsị, na-ebelata oge nkwụsịtụ ma na-ebuli arụpụta ihe.

Ahụmịhe afọ nke ịghasa nhazi nhazi na-enye anyị ohere ịkwalite arụmọrụ nke extruder ọzọ. Site n'enyemaka nke teknụzụ sọftụwia dị oke ọnụ, anyị nwere ike hazie nchikota nke skru. Nke a pụtara na anyị extruders nwere ike rụọ ọrụ nke ọma nyefee na plasticize ihe onwunwe, na-ekwe nkwa a na-agbanwe agbanwe elu àgwà mmepụta. Teknụzụ sọftụwia anyị na-arụ ọrụ dị mkpa n'inweta ọnọdụ ọrụ kachasị mma, na-ahụ na ndị ahịa anyị nwere ike imepụta akwụkwọ PET kachasị elu.

Uru ọzọ dị ịrịba ama nke ejima anyị ịghasa plastic extruders bụ ha versatility. Ma ị na-emepụta mpempe akwụkwọ PET maka nkwakọ ngwaahịa, thermoforming ma ọ bụ ngwa ọ bụla ọzọ, ndị extruders anyị nwere ike gboo mkpa gị pụrụ iche. Ọ nwere ike ịhazi ihe dị iche iche dị iche iche, na-enye mgbanwe dị ukwuu na usoro mmepụta gị. Ọzọkwa, e mere extruders anyị maka mgbanwe dị mfe na ngwa ngwa, na-enye gị ohere ịgbanwe ngwa ngwa n'etiti ụdị ngwaahịa dị iche iche. Nke a versatility na-azọpụta gị oge na ego, na-eme anyị extruders a ọnụ-irè ngwọta maka gị PET mpempe akwụkwọ mkpa.